Zirconia Sensors leverage the oxygen ion conduction properties of zirconia ceramics at high temperatures. By measuring changes in oxygen potential or resistance, these sensors enable precise detection of gas components (particularly oxygen), offering advantages such as high-temperature resistance, rapid response, and strong stability. They are widely used in industries, environmental protection, transportation, and other fields requiring oxygen content monitoring or gas composition analysis. Below is a detailed classification of their primary application scenarios:

1、Automobile and transportation: the core of exhaust emission control

Oxide zirconia sensor is a key component of the closed-loop control system of automobile engine, mainly used to monitor the oxygen concentration of exhaust gas, so as to achieve the best ratio of fuel and air (空燃比), thus reducing pollutant emissions and improving fuel efficiency.

-Gasoline vehicles: front/back oxygen sensors

-1. Front oxygen sensor (installed on the exhaust manifold): real-time detection of oxygen content in exhaust gas, transmit the signal to ECU (engine control unit), dynamically adjust the fuel injection of the fuel nozzle, so that the air-fuel ratio is maintained in the theoretical value (14.7:1), to ensure the efficient operation of the three-way catalytic converter.

-2. The post-oxygen sensor (installed behind the three-way catalytic converter) monitors the purification effect of the catalytic converter. If the difference between the front and rear oxygen concentration is too small, it indicates that the catalytic converter fails and triggers the fault light (OBD system alarm).

-Diesel vehicles: nitrogen oxide (NOx) control

Through the coordinated work of SCR (selective catalytic reduction) system and zirconia sensor, the urea injection can be accurately controlled, so as to effectively reduce the NOx emissions in diesel vehicle exhaust, meeting the strict emission standards such as National 6 and European 6.

-Other transportation equipment: motorcycles, ship engines, heavy trucks, etc., all through zirconia sensors to achieve emission compliance and fuel optimization.

2、Industrial field: process monitoring and safety assurance

In industrial scenarios, zirconia sensors are mainly used for oxygen content detection in high temperature environment, covering energy, metallurgy, chemical industry and other key links to ensure production efficiency and safety.

-Energy and combustion control

1. Boilers/kilns (e.g., electric boilers, ceramic kilns, glass kilns): Monitor oxygen levels in flue gas during combustion, adjust air-to-fuel ratios (coal, natural gas, heavy oil), prevent excessive air supply from increasing heat loss, and avoid overfueling that causes black smoke and CO emissions. This improves combustion efficiency (saving 5% -10% energy) while reducing pollution.

-2. Gas turbine/internal combustion engine power generation: real-time monitoring of exhaust oxygen concentration, optimization of combustion parameters, to prevent carbon accumulation caused by lack of oxygen or high temperature corrosion caused by oxygen enrichment.

-Metallurgy and heat treatment

-1. Steel smelting: In the converter and blast furnace hot blast furnace, the oxygen content of combustion air and gas is detected to control the combustion temperature, so as to improve the quality of molten steel; in the annealing furnace, the low oxygen environment (oxygen content <10ppm) of inert atmosphere (such as nitrogen) is maintained to prevent metal oxidation.

-2. Non-ferrous metal processing (aluminum, copper): In the holding furnace of molten metal, monitor the oxygen concentration in the furnace to avoid the formation of metal oxides and ensure product purity.

Chemical and pharmaceutical

-1. Hazardous gas environment monitoring: In reaction vessels or storage tanks involving flammable and explosive gases (such as methane, propane), detect the ambient oxygen content (which should be below the "lower explosive limit oxygen concentration") to prevent explosion risks (e.g., high oxygen content may cause gas combustion).

-2. Fermentation process control: In biopharmaceuticals and food fermentation (e.g., beer, yogurt), the dissolved oxygen content in the fermenter is monitored to optimize the microbial growth environment and thereby improve product yield.

3、Environmental protection and emission monitoring: pollutant traceability and compliance

Ozodiac sensor is the core component of fixed pollution source emission monitoring, which is used to monitor the oxygen content in the exhaust gas of enterprises in real time, and provide basic data for the calculation of pollutant concentration (such as SO₂, NOx and particulate matter).

-CEMS System (Continuous Emission Monitoring System): At the chimneys of power plants, chemical plants, and waste incineration facilities, zirconia sensors work in conjunction with other detection modules (such as infrared and ultraviolet sensors) to first measure exhaust gas oxygen concentration. The actual emission concentrations of SO₂ and NOx are then calibrated based on oxygen content (to avoid concentration deviations caused by air dilution). Real-time data is uploaded to environmental protection authorities, ensuring enterprises comply with emission standards.

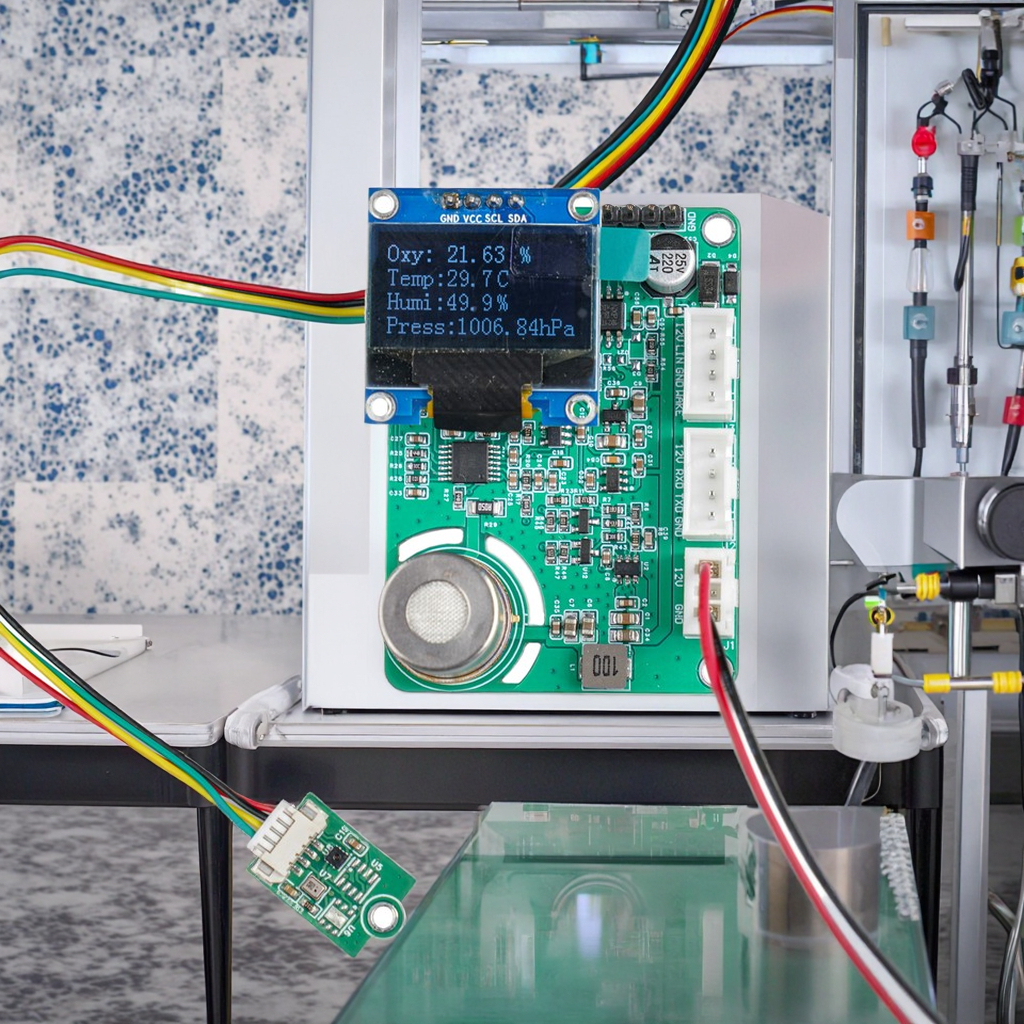

-Indoor air quality monitoring: In a confined space (such as an underground garage, laboratory), the low-power zirconia sensor can monitor oxygen concentration to prevent the risk of hypoxia due to insufficient ventilation (alarm is triggered when oxygen content is below 19.5%).

4、Medical and specialty fields: high precision gas control

Oxide zirconia sensors are used for accurate gas detection in medical and special applications due to their low detection limit and high stability.

-Medical equipment: In ventilators and anesthesia machines, zirconia sensors monitor the oxygen concentration of output gases (such as oxygen and mixed anesthesia gas) in real time to ensure that the oxygen content inhaled by patients meets the treatment needs (to avoid oxygen poisoning or hypoxia).

-Aerospace: In the cockpit of aircraft and life support systems of spacecraft, it monitors the oxygen concentration in the enclosed space to provide a safe breathing environment for astronauts or crew members; it is also used for combustion exhaust analysis of rocket engines and optimization of propellant ratio.

-Food packaging: In modified atmosphere packaging (such as fresh meat, fruits and vegetables, cooked food, etc.), zirconia sensors are used to detect the oxygen concentration in the package (usually less than 1%) to ensure that the food is isolated from oxygen, prolong shelf life and avoid oxidation deterioration.

Summary: The core application logic of zirconia sensors

These sensors are designed for high-temperature, high-precision oxygen detection systems. By leveraging zirconia's ionic conduction properties to convert oxygen concentration into electrical signals, they enable precise control of combustion efficiency, emission compliance, production safety, and life-sustaining systems. With evolving environmental standards (e.g., National VI emission regulations and dual-carbon policies) and advancing industrial automation, zirconia sensors are expanding into specialized applications such as hydrogen detection and miniaturized medical devices.